This is a summary stone crusher project report providing all the relevant details of the jaw crusher as the leading stone crusher in the world. The stone crusher is suitable for use both in primary and secondary setting. The equipment is used in construction, mining, highway, metallurgy and chemical companies and among others. There are various models each depending on your preference and needs.

The stone crusher uses the driving squeezing philosophy. Its principle is such that the motor drives the pulley making the jaw move up and down through the shaft. When the jaw moves up and down, the lining plate opens thus pushing the fixed to the plate. During this stage, the material is crushed until it is small enough.

The stone crusher uses the driving squeezing philosophy. Its principle is such that the motor drives the pulley making the jaw move up and down through the shaft. When the jaw moves up and down, the lining plate opens thus pushing the fixed to the plate. During this stage, the material is crushed until it is small enough.

As the moving jaw is done, the space between the fixed and the lining plate becomes smaller. Next, the material is placed in a rushing room and as the motor keeps circulating, the material continues to be crashed. This is done until there a huge quantity to be released.

Note that stone crushers are a small scale industry owned mostly by people who are less educated. However, over the year, it has grown and has expanded to also include the chemical industry. The problem now is that the equipments have become quite expensive for most people to afford.

March 2012Monthly Archives

Stone Crusher Project Report

Stone Crusher Photos

By looking at stone crusher photos, you will notice that there are various sizes of stone crushers. Each depends with the demand, geographical location and the availability of the material. The stone crushing industry can be divided into 3 categories, large, small and medium.

The small size has can produce materials ranging from 3 to 25 TPH. Such model only has a single jaw crusher which is used as a secondary and also as a primary crusher. Normally, crushers which have two screens are referred to as small stone crushers. Other types of small stone crushers include the crusher with rotary screen and manual feeding operation. This type is usually transported to the construction site and it crushes the material to 8 or 10 inches. The stones are manually separated by about ten to fifteen workers. Almost everything on this machine is manually operated.

The small size has can produce materials ranging from 3 to 25 TPH. Such model only has a single jaw crusher which is used as a secondary and also as a primary crusher. Normally, crushers which have two screens are referred to as small stone crushers. Other types of small stone crushers include the crusher with rotary screen and manual feeding operation. This type is usually transported to the construction site and it crushes the material to 8 or 10 inches. The stones are manually separated by about ten to fifteen workers. Almost everything on this machine is manually operated.

The medium size crushers have only a single crusher with two or more vibrating screens. The stones are transported by dumpers or trucks and then are unloaded to the stone walls. During this process, the stones are fed to the primary crushers using gravity. Then the crushed stones are transported to the vibratory screen using belt conveyors.

The large stone crushers on the other hand have two or more of crushers two or more vibratory screen. They are designed to produce more t100 TPH stones. Such kind of crusher has its own mechanical mining machines and as such, it is quite an investment.

Stone Crusher Parts

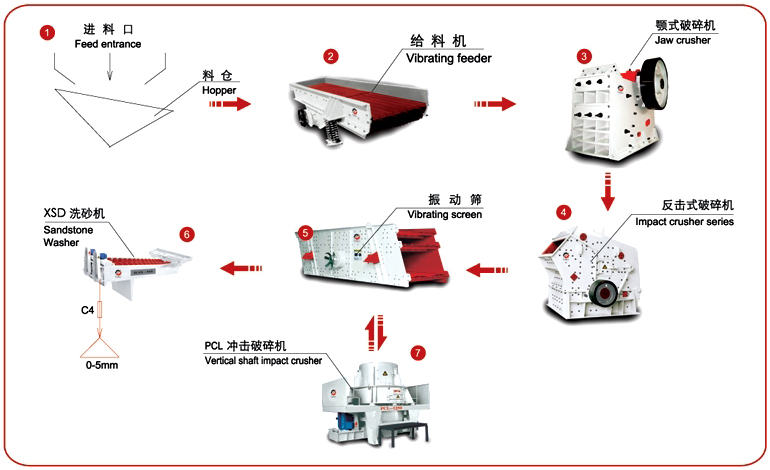

A complete stone crusher parts consists of the following, a crushing equipments, vibrating feeder, second crushing equipment, vibrating screen, sand washer, vibrating feeder electric control panel and the belt conveyor. Note however, that the parts of the equipments depend on the needs of the customer. The parts when assembled together can be used to crush stone for road construction, housing, bridges and cement products.

During the manufacturing process, the granite is fed into the jaw stone crusher so that it can reduce in size and also equalized. Depending on the size that you want, the crushed stone can be put in the jaw crusher several times. After that, the crushed stones are passed to the rotary screen for gradation of the size. Note that the material is placed on to the conveyor as it passed to different part. This means that the belt conveyor acts a transportation system for the materials.

The demand for the crushed stone continues to grow as houses are important in the society. All the constructions whether it is industrial or housing needs the usage of crushed stone. Additionally, also cement based products such as PSC pipes, RCC pipes and slabs require the usage of crushed stone. Note that the demand for crushed stone will continue to grow as the growth of its usage grows.

When you considering buying the stone crusher parts, make sure that they are compatible with the model that you have. If possible purchase from the same manufacturer where you bought the original.

Stone Crusher Plant

The stone crusher plant consist of equipments such as a jaw crusher, vibrating feeder, electric system, impact crusher, belt conveyor and vibrating screen. These equipments are normally reliable, good performance, top technology and good structure. The plants usually have a design capacity ranging from 50 to 500. It ought to be noted that sometimes the plant is designed to meet the requirements of the buyer. They may include machines such as the dust catcher, cone crusher, stone catcher and washing machine.

The Stone Crusher Plant Application

The stone crusher plant is normally used in construction, mining and highway railroad and among others. Africa and India is known to be major users of this application because of the presence of minerals and other resources in this country. The crusher is mainly of three types, the sleigh, portable and fixed. The screening and crashing capability can be as high as 500 and as low as 50. Additionally the size of the crushed material can be 0 to even 40. The size is dependent on the needs of the customer.

Note that the crushed stone is in aggregate form and when it is loaded onto the plant, it is crushed into a suitable size. The machines that are used for crushing the rock include the primary jaw, hydraulic impact and the hydraulic cone crusher. Unlike gravel which is as a result of natural causes, the crushed stone is shaped onto a particular size and when crushed it is used in making rail road.

Jaw Stone Crushers Sale

Jaw stone crusher is very popular equipment that is used for crashing stone. It is equipment that is mostly used in basalt crushing plant, stone quarry plant and limestone production. One of the things that have made jaw stone crusher is that can crush large rocks in the shortest time possible. In addition, it can also crush the stones evenly regardless of the size of the material. The model 320 Mpa is used mainly for crushing while the PEX is used to grind into finer materials. Over the recent years, the stone crusher equipment has developed and is now used by many industries such as hydropower, quarry and minerals and among others.

Advantages of Jaw Stone crushers

The jaw stone crusher is highly effect and has a large crushing capacity with little dust and low noise. Additionally, it has a crushing depth which improves the feeding capacity and output. The adjustable device near the rear end makes it flexible, convenient and reliable to use. Last but not least, it saves on energy because of the large crashing ration.

There are various manufacturing companies which offer jaw stone crushers sale bat reasonable prices. Before you purchase, make sure that you do an extensive research on the company and determine if it is reputable. Also compare the prices and see if you can afford it. If you have any question concerning the equipment, make sure you have it clarified before making the purchase. Lastly, buy a jaw stone crusher that fits your needs and preference.

Jaw stone Crusher India

Jaw stone crusher is very important equipment that is used in construction sites, quarries and other pieces of large rocks. Because of its great importance, it is necessary to ensure that the machine is reliable and performs effectively before you decide to purchase. In addition, make sure that the equipment can perform the entire intended task in terms of breaking down the huge rocks. Note that the jaw stone crushers cones in various shapes and sizes. As such, you need to ensure that the material you choose is worth and can perform efficiently.

Besides shapes, the jaw stone crusher India comes in many capacities. This means that the container can hold a certain ton of material when processing. As you choose the equipment, make sure that you choose one that fits with your needs. In addition to that, the equipment is also sold in various prices. Each manufacturer has his own price. This is dependent on the size, shape and capacity of the equipment.

In order to get the best price, you need to do an extensive research in order to get equipment that fits to your preference and needs. Make sure that you make the best choice because equipments are like an investment and if they break down easily, you will be running on losses.

How to Choose a Jaw stone Manufacturer

How to Choose a Jaw stone Manufacturer

There are various manufacturers in the world and because of this, it might get confusing when attempting to choose one. When choosing a jaw stone crusher India, make sure you look at their reputability. Go for manufacturers who are highly reputable as you will be guaranteed of a high quality product. Try as much as possible to get a manufacturer who matches to your needs. This is in terms of prices and even the customer care service. This is very important as it will help you make an informed decision on the equipment to choose.