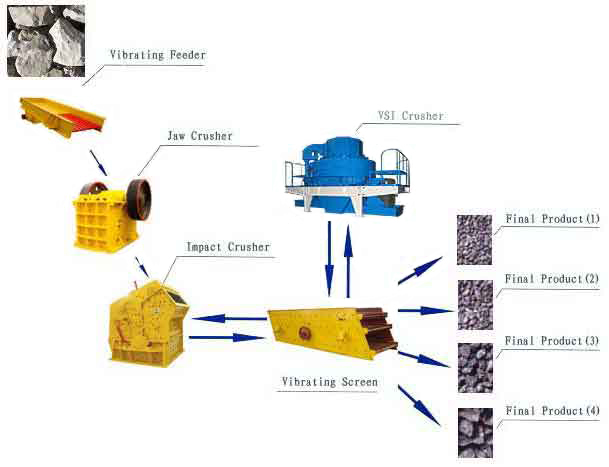

Stone crusher wiki lets you understand the basic information about the stone crusher. This is a machine that is used to crush stones that have been mined and this happens in a milling plant. The machine reduces large rocks into smaller rocks or even to dust powder. Crushers are of different sizes and each has different task to perform at separate stages. The main aim of the crusher machinery is to change form to enable transport or manufacturing easier since the machines used in manufacturing are of a different nature.

Stone crusher wiki helps you understand that the crushing devices found in the machine, hold the raw material in between the solid surfaces then apply force which is sufficient enough to bring the surfaces together to assist in crushing the stone. The crushing process transfers forces that have been amplified using a mechanical advantage made of molecules.

Stone crusher wiki helps you understand that the crushing devices found in the machine, hold the raw material in between the solid surfaces then apply force which is sufficient enough to bring the surfaces together to assist in crushing the stone. The crushing process transfers forces that have been amplified using a mechanical advantage made of molecules.

Technology has made everything easier from the days where crushers were just two stones that were held together. After that the machinery that was used did not give fine powder end product in a short time like today’s machines. There are modern machines that economize on space, power and also general cost. Due to manufacturing competition you will find legitimate manufacturers will always offer a service warrant of at least one year.