Coal is usually mined from the earth, but before it can become useful, it has to be taken to a coal crushing plant so that it can be washed and any impurities can be removed from it. The size of coal has to be significantly reduced in order to increase its contact area, and this is how the energy of coal is used efficiently.

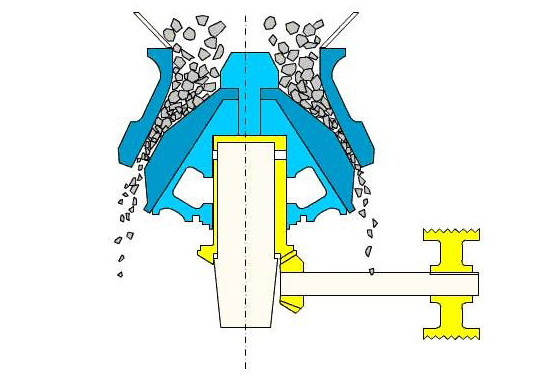

There are several equipment in a coal crushing plant including a jaw coal crusher which is the most common, an impact crusher which is also commonly used in the crushing of coal and a cone crusher which crushes the coal into fine particles. There is also a hummer crusher which is mostly used in the process of milling.

When processing coal, natural coal is first fed into the jaw crusher using a belt conveyer and then it is crushed. After that, it enters the impact crusher or the cone crusher where it is crushed into finer particles. Finally, the coal is screened out using a screening machine.

For coal to be used more efficiently, it has to be crushed into different sizes depending on how it will be used. The size of coal used in a coal gas stove is different from the one used in a steam locomotive or in an industrial furnace. Therefore the coal crushing plant prepares coal by both crushing it and milling it.